Did you know you can’t stop pressure washing without shutting down the machine? Well, you can, but you shouldn’t.

Without a pressure washer unloader valve, you can meet dangerous when use pressure washers if you step away to answer the phone, chase the dog, or chat with the neighbors.

Why? When you release the spray wand trigger, the engine is still on, but the pressure is not removed. This high-pressure buildup can cause severe damage to your machine.

An unloader valve is essential if you use your pressure washer regularly. By regulating system pressure, this tool can help you avoid costly repairs or replacements.

What is a pressure washer unloader valve?

Essentially, the unloader valve is a safety switch. It circulates pressurized water from the outlet side of the pump to the inlet or tank, sending it to the bypass. This process depressurizes the water and prevents pressure buildup when the pressure washer is idling.

How does pressure washer unloader valve work?

Think of this trapped pressure unloader as a pressure relief valve. Depending on the type of unloader valve, it is activated by either a decrease in flow or an increase in pressure. When you release the trigger gun, the valve simply activates its spring and checks the ball mechanism, sending water into the bypass.

A spring and ball mechanism diverts the water flow from the nozzle and delivers it continuously from the outlet side of the pump system to the inlet side. This happens unless you pull the wand trigger again.

When you activate the pressure washer wand again, the flow-driven unloader will shut off and redirect the water to the nozzles.

Why do you need pressure washer unloader valve?

First, for safety. You can turn your electric pressure washers on and off with a switch. Depending on your hose length, you may be far from the machine.

Any incidents can quickly take you off the pressure washing job. You probably don’t have time to run back and turn off your pressure washer.

For example, you may have an important work call, an emergency, or your dog is out. Unexpected events always happen!

A pressure washer unloader valve enables you to leave the machine safely.

Without an unloader valve, the water pressure in the nozzle would continue to build, possibly resulting in a very unsafe situation.

An increased pressure can cause the water pressure to exceed the PSI limit, potentially damaging the pressure washer’s pump.

Using an unloader valve will ensure the safe operation of the machine and prolong its life.

While the increased safety is undoubtedly a benefit, the unloader valve is also straightforward. It allows you to adjust the spray gun’s working pressure while working.

Advantages of using unloader valves for pressure washers

Improved safety

The pressure washer unloader valve prevents built-up pressure from exploding from the pressure washer wand and injuring you or others or damaging the project you are working on.

Avoid Damage

In an emergency, you can safely release the pressure wand trigger and solve the emergency without worrying about damaging your machine.

Easier to use

You can easily adjust the pressure flow with the pressure washer unloader valve.

Disadvantages of using unloader valves for pressure washers

Pressure Problems

Improperly installed or adjusted valves can cause pressure problems. Pressure problems are caused by improperly tightening or loosening the spring in the unloader valve. Also, the use of incompatible valves may result in a pressure drop.

Heat Buildup

Allowing water to circulate for too long can cause heat buildup, leading to costly damage.

Tip: Don’t ever leave your pressure washer in bypass mode too long. If left too long, the water may heat at extremely high temperatures, causing the o-rings to soften and corrode the pump.

Types of pressure washer unloader valves

There are two types of unloader valves.

Depending on whether your unloader valve is pressure actuated unloading valve or flow actuated unloader valve, your unloader valve may operate in one of two ways.

Pressure-actuated unloader valve

The gun’s valve opens when you depress the trigger using the pressure-actuated unloader valve, expelling water through the nozzle.

This reduces the pressure on the unloader valve, allowing water from the pump to flow directly to the nozzle.

When the trigger gun’s valve is closed by releasing the trigger, pressure builds up on the unloader valve, forcing it to unload or recirculate back to the reservoir.

Unloader valve with flow control

This valve system works in the same way as a flow-actuated unloader valve.

The unloader, on the other hand, is controlled by the flow rate.

In this case, a piston is used instead of a spring, and if the flow decreases, the unloader will begin to recirculate water back to the pump inlet or tank.

How to adjust or rectify a trapped pressure washer unloader valve

To adjust the trapped-unloader valve, press the trigger and loosen the screw on the body to relieve spring tension.

Release the trigger to check that the unloader is working. Pressing it again allows the system to build up its operating pressure when it’s time to adjust.

If unsatisfied, you can tighten the bolt while pulling the trigger.

This process should be repeated until the desired pressure is achieved. Be sure to check the pressure gauge each time you adjust.

How to adjust or rectify a flow-actuated pressure washer unloader valve

Adjusting flow actuated unloader valves work in the same way.

Bypass pressure will rise when the adjusting nut is tightened, whereas bypass pressure will fall when the adjusting nut is loosened.

When making adjustments, ensure the peak pressure is not 200 PSI higher than the working pressure, or you may damage the machine.

Empower your cleaning endeavors with the right pressure washer and its vital component, the unloader valve. If you’re seeking top-quality pressure washers or need guidance on maintaining and optimizing their performance, China professional pressure washer manufacturer BISON is here to assist. Reach out to us today to explore our range of pressure washers, pressure washer accessories, and expert advice. Let’s ensure your cleaning tasks are not just efficient but also performed with precision and ease. Contact us now to discover the perfect pressure washer solution tailored to your needs!

Pressure Washer Unloader Valve FAQs

Some signs will tell you if the unloader valve needs to be replaced. Please note the following points:

- water leakage

- pressure loss in the machine

- The high-pressure washer engine stalled

- The thermal release valve releases steam

Although you should check for other problems like clogs, pressure washer troubleshooting may point to the unloader valve as the reason.

Firstly, set up for adjustment.

- Make sure the pressure washer is on a flat surface.

- Start the engine, keep the speed at 3700 rpm before load, and keep the speed at 3400 rpm under load.

- Remove the nylon lock located inside the unloader valve.

- Close the pressure regulator nozzle.

- Remove the gasket and spring from the unloader valve. Do you see the threaded piston with the two locknuts?

- Take a wrench and tighten both nuts.

- Unscrew the three threads from the bottom and put the spring, washer, and nut back in their place.

- Clip the pressure between the high-pressure hose and the pump. Be aware of these when you make unloader valve adjustments.

Secondly, Adjust the unloader valve.

- Open the outlet valve on the pressure washer. Please do not turn it off until only water flows out of the house. The main goal is to remove all air.

- Tighten the compression spring, but pay attention to the pressure gauge assembly.

- Pull the pressure washer wand trigger until maximum pressure is reached. Pressure spikes should be approximately 6% to 9%.

- If the pressure spike is above 10%, adjust the nut until you see a pressure spike below 10%.

- If your reading is still not below 10%, then you may need to remove and adjust the adjustment knob, washer, and spring.

- Twist the unloader several times to break it in.

- Replace washers, springs, and knobs.

- Check the gauge one more time before screwing everything back into place.

- Make sure to put the unloader valve cap back on.

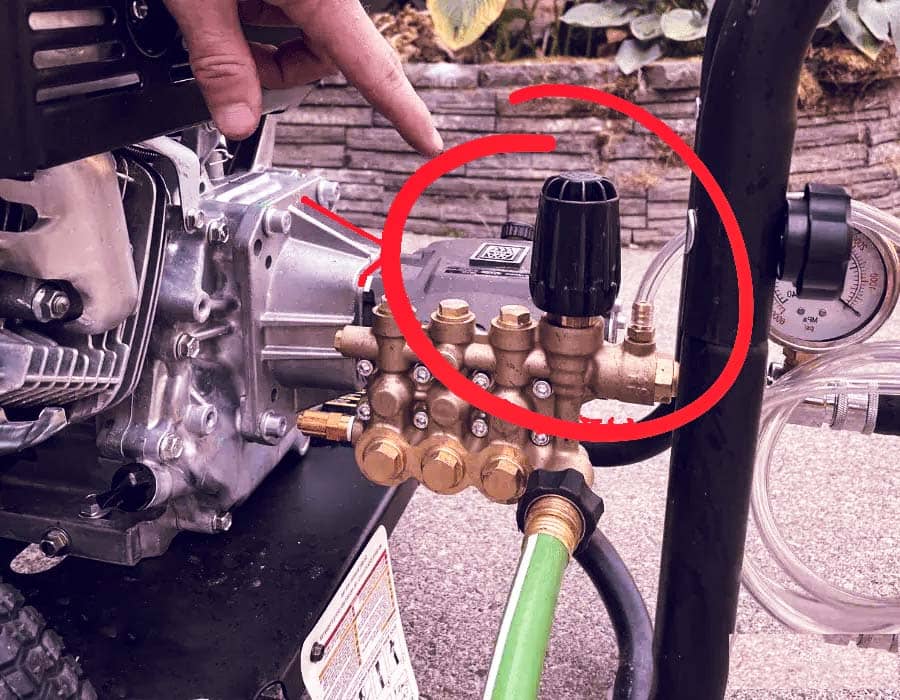

A built-in unloader valve is standard on most pressure washers. The valve mechanism inside the pump casing is not easily accessible or replaceable.

However, an externally mounted unloader valve is a separate unit connected to the outside of the pump casing. This makes them easier to find and replace when needed.

Some external unloader valves come with a hose as part of the mechanism, allowing pressurized water to travel greater distances when the pump is in bypass mode. This reduces heat buildup within the pump, reducing the possibility of thermal damage.

Disconnect the high-pressure line from the pump and connect the garden hose to the faucet. If this does not happen, there is a problem with the internal pump. If this happens, there is a good chance that one of the accessories is clogged, such as a high-pressure hose, wand, cannon, or nozzle.