Pressure Washer Axial Flow Pumps

Manufacturer & Supplier

With its maintenance-free design that eliminates the need for oil changes, the axial flow pump has become the top choice for residential pressure washers. BISON provides axial flow pumps in vertical and horizontal mount configurations, catering to varying installation preferences.

P170V

OEM Technologies Axial Vertical Pressure Washer Pump 2400 PSI at 2.0 GPM

2400-2700PSI, 2.4GPM, 7/8Shaft,Axial Vertical

Axial Pump-Vertical

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine: 5.5hp/6.5hp/7hp

Pump Head:Brass

Hollow shaft: 22.23mm

Keyway:4.78mm

P180V

2800 PSI 2.5 GPM 7/8″ Hollow Shaft Vertical Pressure Washer Pump Unloader

2800-3200PSI, 2.5GPM, 7/8Shaft, Brass Head, M22*14

Axial Pump-Vertical

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine: 5.5hp/6.5hp/7hp

Pump Head: Brass

Hollow shaft: 22.23mm

Keyway:4.78mm

P170VL

2400-2700 Psi, 2.5GPM Power Washer Vertical Axial Flow Pump Replacement Parts

2400-2700PSI, 2.5GPM, 7/8Shaft, Lengthen Outlet

Axial Pump-Vertical

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine: 5.5hp/6.5hp/7hp

Pump Head: Aluminum

Hollow shaft: 22.23mm

Keyway:4.78mm

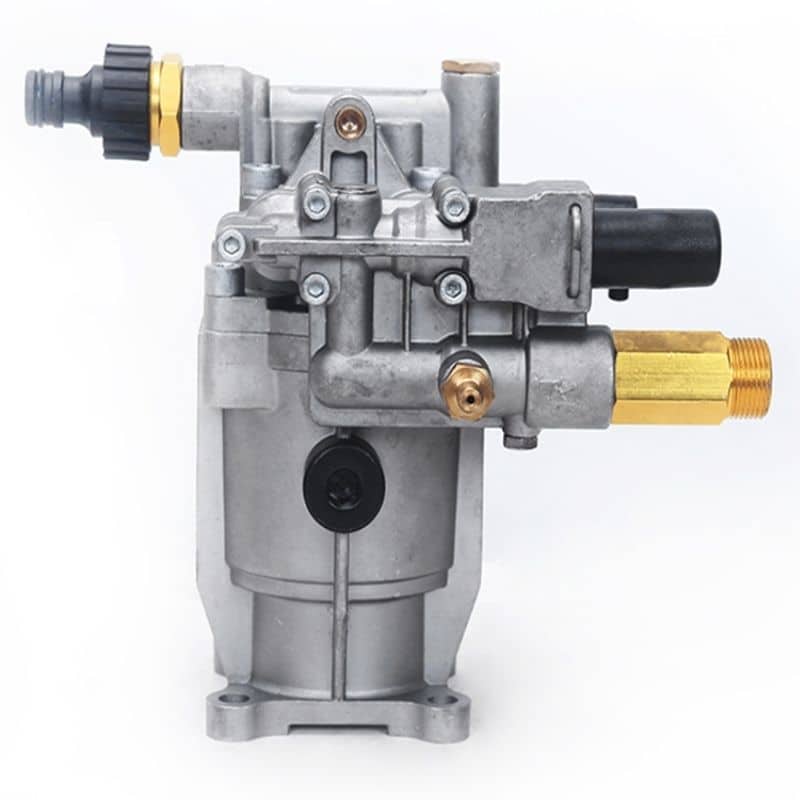

P170HB

OEM Axial New Replacement Cold Water Pressure Washer Pump 3000 PSI

Max 3000PSI, 2.5GPM, 3/4 Shaft, Inlet for Garden Hose

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine Power : 5.5hp/6.5hp/7hp

Pump Head: Aluminum

Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

P170HY

2000 Psi Best High Pressure Washer Pump 5h 5hp For Washing Machine

2000-2200PSI, 2.5GPM, 3/4 Shaft, Inlet for Garden Hose

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine Power : 5.5hp/6.5hp/7hp

Pump Head :Aluminum

Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

P170H

2800 PSI Aluminum Gasoline Cold Pressure Washer Pump 2.5 GPM

Max 2800PSI, 2.5GPM, 3/4 Shaft, Inlet for Garden Hose

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine Power : 5.5hp/6.5hp/7hp

Pump Head :Aluminum

Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

P170H-1

2400-2800 PSI Pressure Washer Pump 3/4″ Horizontal Replacement

2400-2800PSI, 2.4GPM, 3/4Shaft

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine Power : 5.5hp/6.5hp/7hp

Pump Head: Aluminum

Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

P180HB

Horizontal Brass 3100 PSI Maximum High Pressure Cleaner Washer Pump

3100-3200PSI, 2.4GPM, 3/4Shaft

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine Power : 5.5hp/6.5hp/7hp

Pump Head: Aluminum

Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

P180H

3000 PSI 2.4 GPM Pressure Washer Pump 3/4″ Shaft OEM Replacement

2400-3000PSI, 2.4GPM, 3/4Shaft

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine Power : 5.5hp/6.5hp/7hp

Pump Head: Aluminum

Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

P180H-1

Horizontal Replacement Power Pressure Washer Pump 3000 PSI 2.5 GPM 3/4in Shaft

3000PSI, 2.4GPM, 3/4Shaft, Brass Pump Head

Axial Pump-Horizontal

Pressure :150-200bar/2200psi-3000psi

Flow Rate:9lpm/2.4gpm

Drive:Engine Driect

Engine: 5.5hp/6.5hp/7hp

Pump Head :Brass Hollow shaft: 3/4″ /19.05mm

Keyway:4.78mm

Find a high pressure washer pump that takes your pressure washing business to the next level.

Why Choose BISON Axial Pressure Washer Pump

Axial Pressure Washer Pump Advantages

BISON Axial pressure washer pumps are known for their simplicity and efficiency in converting rotary motion into high-pressure water flow. They are lightweight, compact, and easy to maintain, making them ideal for portable pressure washer units. Axial pumps are capable of generating high pressures, suitable for most residential and light commercial cleaning tasks.Their design allows for easy access to key components for quick repairs and maintenance. Overall, axial pressure washer pumps offer a cost-effective solution for those looking for reliable and efficient cleaning power.

Factory direct sales

When it comes to BISON axial pressure washer pumps, factory direct sales offer several advantages. By purchasing directly from the factory, customers can benefit from competitive pricing and cost savings without any intermediary markups. Factory direct sales also ensure higher product quality control, as there is a direct link between the manufacturer and the customer. Customers can enjoy personalized customer service, quick response times, and tailored solutions to meet their specific needs. Overall, factory direct sales of BISON axial pressure washer pumps provide a seamless buying experience, reliable products, and excellent value for customers.

Find a high pressure washer pump that takes your pressure washing business to the next level.

BISON Axial Pressure Washer Pump Wholesale Guide

What is the axial pump?

An axial pump, also known as an axial pressure washer pump, is a type of pump commonly used in pressure washer systems. It works by converting rotary motion, typically from an electric motor or engine, into high-pressure water flow. The design of the axial pump allows it to generate high pressures suitable for cleaning tasks. Axial pumps are known for their simplicity, efficiency, lightweight construction, and easy maintenance. They are widely used in residential, commercial, and industrial settings for various cleaning applications.

What are the benefits of axial flow pump?

Axial flow pumps, also known as axial pumps, offer several benefits:

- Efficiency: Axial flow pumps are known for their high efficiency in moving large volumes of water at relatively low heads. This makes them ideal for applications where high flow rates are required.

- Low head requirements:Axial flow pumps are designed to operate efficiently with low head requirements, making them suitable for pumping water over long distances or in applications where traditional pumps would struggle.

- Space-saving:Axial flow pumps have a compact design, taking up less space compared to other types of pumps while still delivering high flow rates. This makes them suitable for installations where space is limited.

- Low maintenance: Due to their simple design and fewer moving parts, axial flow pumps typically require lower maintenance compared to other pump types. This can result in cost savings over the pump’s lifespan.

- Versatility: Axial flow pumps can be used in a wide range of applications, including irrigation, drainage, wastewater treatment, and cooling systems. Their versatility makes them a popular choice for various industries and settings. Overall, the benefits of axial flow pumps include efficiency, low head requirements, space-saving design, low maintenance needs, and versatility in different applications.

What the difference between Axial pump and Triplex pump?

The key differences between axial pumps and triplex pumps lie in their design and operation:

1. Design:Axial Pump:

Axial pumps have a simpler design with a single piston moving back and forth along the axis of the pump cylinder. They typically have fewer moving parts and a more straightforward construction.

Triplex Pump:Triplex pumps have three pistons or plungers arranged in a radial pattern around a crankshaft. This design allows for smoother and more continuous flow of water compared to axial pumps.

2. Pressure Output:

Axial Pump:Axial pumps are more suited for applications requiring higher flow rates but relatively lower pressures, such as in residential and light commercial pressure washers.

Triplex Pump:Triplex pumps are capable of generating higher pressures while maintaining a consistent flow rate, making them suitable for heavy-duty industrial applications like high-pressure cleaning, water blasting, and hydraulic systems.

3.Efficiency and Smoothness:

Axial Pump: Axial pumps are generally less efficient and can produce pulsating flow due to the single piston design.

Triplex Pump: Triplex pumps are known for their high efficiency and smoother flow delivery, resulting from the balanced operation of three pistons.

4. Maintenance and Durability:

Axial Pump: Axial pumps are simpler in design and have fewer moving parts, leading to easier maintenance and potentially lower maintenance costs.

Triplex Pump:Triplex pumps are more complex with multiple pistons and valves, requiring more maintenance and expertise for upkeep.

However, they are often more durable and suitable for continuous heavy-duty use.

In summary, axial pumps are simpler, more cost-effective, and suitable for low to medium pressure applications, while triplex pumps offer higher pressure capabilities, smoother flow, and durability for demanding industrial applications.

If you want to learn more, check BISON guide Axial pump vs Triplex pump.