BISON Santy

Hello, I am Santy, the funder of bisonclean.com. I have been in cleaning machinery field for more than 5 years now, and the purpose of this article is to share with you the knowledge related to pressure washer from a Chinese supplier's perspective.

Table of Contents

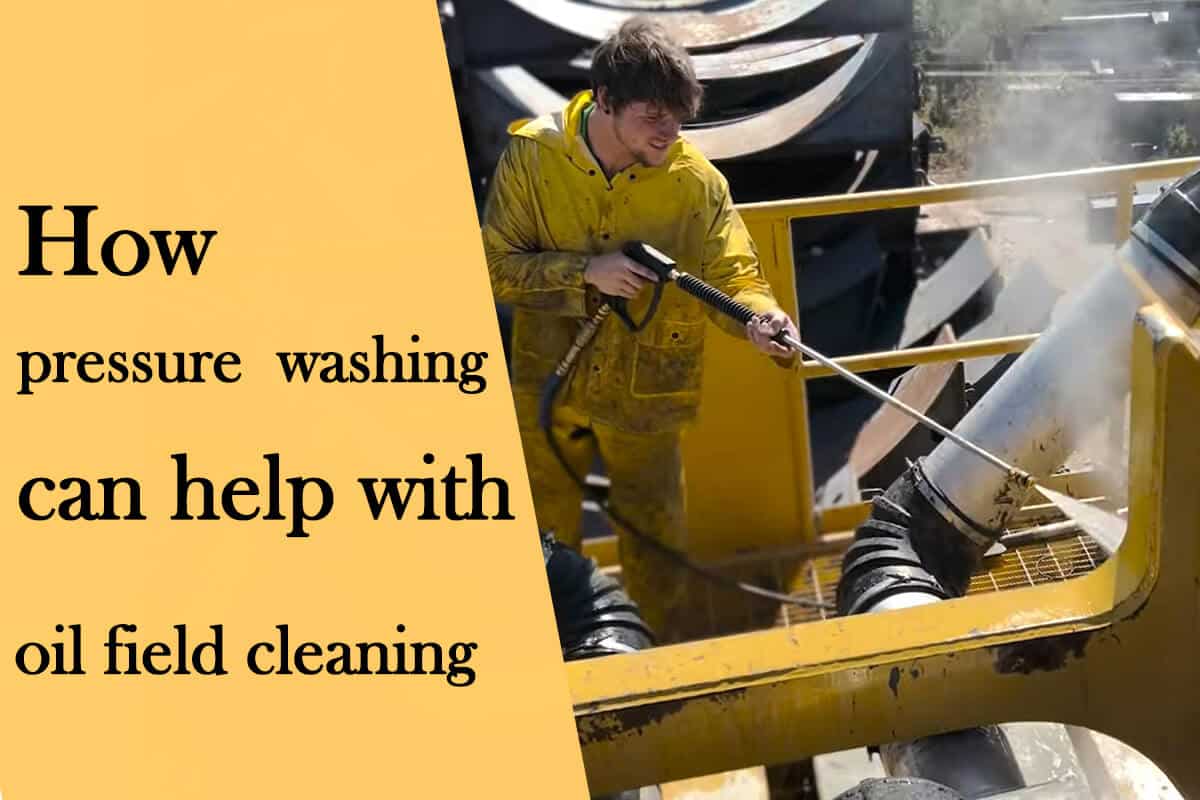

The oil industry is one of the world’s most important and complex industrial sectors. It operates in demanding conditions that present unique challenges for equipment maintenance and operational integrity. In this high-risk environment, keeping oil fields clean and operating efficiently is no easy task. The industry faces three major challenges: stringent safety standards, highly regulated environmental compliance, and the need to continually optimize operational efficiency.

The accumulation of oil spills, sludge, and industrial residues poses a significant risk not only to worker safety but also to equipment life and environmental compliance. Through the high-pressure water flow, precision-engineered nozzles, and specialized cleaning agents provided by pressure washers, this article will show how pressure washing can provide a cleaning solution for the oil field industry and explore its benefits and applications.

Challenges of oil field cleaning

Harsh environmental conditions and complex contaminants

The wide variety of oil field pollutants and harsh operating conditions not only affect mechanical performance but also pose safety hazards to workers and the environment. The following pollutants are commonly generated:

- Petroleum hydrocarbons: Crude oil, heavy grease, and various petroleum derivatives that create stubborn, adhesive residues

- Naturally occurring radioactive materials (NORM): Radioactive scale and sludge

- Inorganic materials: Salt deposits, drilling mud, sand, and mineral scale

- Metal contaminants: Rust, metal shavings, and wear particles from equipment

- Chemical compounds: Production chemicals, drilling fluids, and treatment additives

- Toxic substances: Volatile organic compounds (VOCs) and hazardous materials

Key reasons for oil field cleaning

Limitations of traditional cleaning methods

- Accessibility issues: Traditional methods have difficulty reaching areas with complex equipment geometries, have limited effectiveness in confined spaces and complex mechanical parts, and have difficulty accessing overhead or remote equipment components.

- Performance limitations: Manual cleaning methods lack the impact required to remove stubborn contaminants, and chemical cleaning agents alone may not accelerate the decomposition of persistent hydrocarbon deposits, a process that often results in extended equipment downtime.

- Safety and environmental issues: Chemical cleaning agents may pose additional environmental risks, manual cleaning exposes workers to hazardous substances, and traditional methods typically generate more waste and wastewater that need to be disposed of.

Above, if you need to know more, please check out “Pressure washing vs. traditional cleaning methods“.

The hidden dangers of incomplete cleaning

- Equipment impact: Increased wear and corrosion of key parts of the equipment, reduced operating efficiency and equipment performance, and ultimately shortened equipment life, failures, and increased maintenance costs.

- Environmental impact: Leaching pollutants lead to soil and groundwater contamination, volatile compounds lead to deterioration of air quality, and non-compliance with environmental regulations may result in huge fines and remediation costs.

- Safety hazards: Hydrocarbon accumulation leads to an increased risk of fire and explosion, and oil-contaminated surfaces cause slip and fall hazards. There is also a risk of personnel exposure to chemicals, and emergency response efficiency will also be impaired.

How pressure washing meets oil field cleaning challenges

How pressure washing works and what it does

Water is propelled through a high-pressure pump system, generating a high-pressure water flow in the pressure washer, which is concentrated and directed through a special nozzle when the water flows out. Its pressure level can be adjusted from 1,500 to 5,000+ PSI according to different applications, and it can usually reach a flow rate of 3 to 8 gallons per minute.

The kinetic energy generated by pressure washing breaks the molecular bonds between contaminants and surfaces, and the high-pressure impact can remove stubborn deposits. The use of a concentrated spray pattern provides precise cleaning control, and when pressure washing combines mechanical and chemical actions, it can also enhance the cleaning effect.

Targeted selection of pressure washers

Hot water pressure washer: Operating at temperatures up to 200°F, it is ideal for breaking down heavy oils and greases and dissolving paraffin deposits. Hot water pressure washers also reduce cleaning time and chemical usage and disinfect equipment surfaces.

Cold water pressure washer: This is a more economical cleaning device for general equipment cleaning. Mainly used for removing dirt and debris, heat sensitive areas.

Specialized accessories for oil field pressure washing

- Pressure washer nozzles (0° pencil nozzle, 15° fan nozzle, 25° universal nozzle, 40° wide nozzle, rotary turbine nozzle, adjustable pressure nozzle.)

- Pressure washer telescoping wand

- Pressure surface cleaner

- Pressure washer hose reel

Main advantages of oil field pressure washing

Fast and effective cleaning

The powerful water jets of pressure washing produce immediate results, significantly reducing hours of cleaning time compared to manual methods.

Under the action of the nozzle, the pressure washer provides adjustable pressure levels and is able to quickly and efficiently cover large surfaces, saving up to 70% of water over traditional cleaning methods. Hard-to-reach corners can also be cleaned.

Equipment performance enhancement

Using pressure washing to remove contaminants is very thorough, and it cleans equipment to near original operating conditions, including improving heat transfer efficiency in heat exchangers and optimizing fluid flow in pipelines and process equipment.

Maintain protective coatings and surfaces by thoroughly removing corrosive materials and scale buildup, extending equipment life.

Safety and compliance

Oil leaks or grease accumulation can cause accidents or health hazards, and pressure washing is the most effective solution. High-pressure water can quickly break up and flush away the oil, allowing the scene to be promptly handled and controlled.

Regularly cleaning grease accumulation, removing flammable residues, and cleaning safety signs, indicators, and workspaces through pressure washing can prevent accidents.

This cleaning behavior also indirectly removes harmful chemical residues and airborne particles, improves the overall hygiene of the workplace, and allows oil field work areas to meet environmental regulations.

Cost-effectiveness

Pressure washing is an inexpensive cleaning method, especially compared to other cleaning technologies.

Low maintenance cost: BISON pressure washers are easy to maintain and maintenance accessories are inexpensive. They can be used for a long time without catastrophic equipment failure.

Operational savings: simplify personnel expenses and optimize water consumption and chemical needs.

Applications of pressure washing in oil field operations

- Drilling platform and equipment cleaning

- Tank and container cleaning

- Oil spill and pollution management

- Pipeline and refinery cleaning

- Coating and surface preparation for repair

- Wellhead and valve cleaning

- Transport vehicle and loading area cleaning

- Maintaining environmental regulations in oil field work areas

Conclusion

The implementation of pressure washing technology in oil field operations represents a critical intersection of operational efficiency, safety compliance, and environmental stewardship. Throughout this article, BISON has demonstrated how modern pressure washing solutions deliver multiple essential benefits. If your oil field is facing a cleaning adjustment, it’s time to choose pressure washing.

As a leading manufacturer of pressure washer equipment, BISON is at the forefront of innovation and reliability in the cleaning equipment industry. For oil field operations, you can’t go wrong by choosing BISON to meet your cleaning needs. Contact us today to learn how our pressure washer solutions can optimize your operations, improve safety, and ensure environmental compliance.

FAQs about pressure washing oil field

The special requirements of oil field operations determine how often pressure washing should be done. BISON recommends that you develop a regular cleaning schedule: a thorough cleaning every few weeks or after major operations.

It is not always effective on certain types of industrial residues, such as severe scale buildup, deep rust, or extensive oil spills, which may require additional equipment and techniques.

The correct pressure and water treatment methods can reduce the risk of contaminating nearby soil or water. In addition, it is crucial to use biodegradable chemical cleaning solutions during the cleaning process.

You might also enjoy

Questions?

Contact Us Today.

Related Products

Find more?

Related Posts

Pressure washer is surging/pulsing

we’ll help you understand why your pressure washer is surging and guide you through easy steps to fix it so you can get back to

How to clean pool tiles with a pressure washer

This comprehensive guide will walk you through the steps to restore your pool tile to its original glory using a pressure washer.

Pressure washing vs. traditional cleaning methods

In this article, BISON will take an in-depth comparison of pressure washing vs. traditional cleaning methods to highlight their pros and cons.

Why is my pressure washer smoking

This blog will help you understand the common reasons why your pressure washer may smoke. In the end, you’ll learn what the smoke could mean