BISON Santy

Hello, I am Santy, the funder of bisonclean.com. I have been in cleaning machinery field for more than 5 years now, and the purpose of this article is to share with you the knowledge related to pressure washer from a Chinese supplier's perspective.

Table of Contents

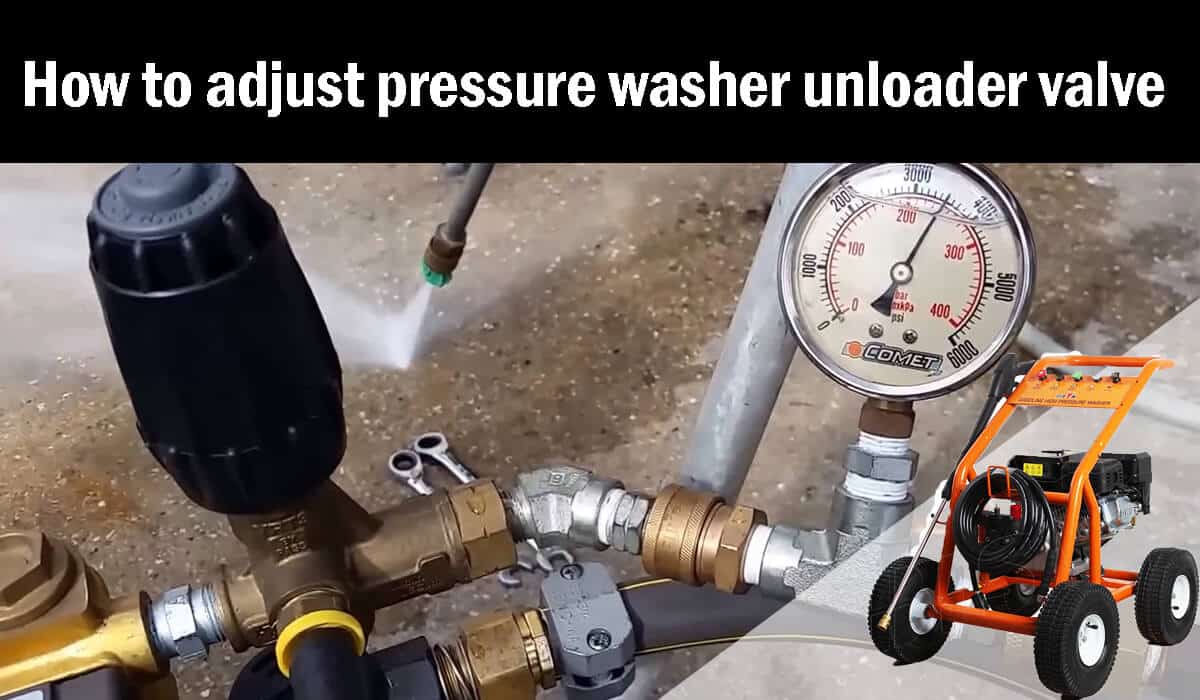

Pressure washer unloader value ensures the pressure washer operates at its intended pressure range, maximizing cleaning efficiency. Moreover, it enhances safety by preventing excessive pressure build-up that could lead to hose ruptures or other hazardous situations. Many pressure washer owners and operators find themselves needing to adjust the unloader valve from time to time.

Are you worried about how to adjust the BISON pressure washer unloader valve? This comprehensive guide will demystify adjusting the unloader value and provide steps on how to effectively adjust the unloader valve on your pressure washer. By following the BISON guide, you’ll be able to maintain your pressure washer’s performance, extend its lifespan, and ensure safe operation for years to come.

What is a pressure washer unloader valve?

The pressure washer unloader valve is the most crucial component of the pressure washer, and it is responsible for the high-pressure water that shoots out of the spray gun. It works by redirecting water flow when the trigger gun is released, preventing pressure build-up and potential damage to the pump and other components.

Water enters the bypass valve when the trigger gun is released, triggering the valve’s spring and ball check mechanism. A spring and ball mechanism deflects the water flow from the spray nozzle and sends it continuously from the outlet side to the inlet side of the pump system. This happens until you pull the stick again.

Its primary functions include:

- Bypass control: Redirecting water flow when the trigger gun is released to prevent pressure buildup.

- Pressure regulation: Maintaining consistent pressure output during operation.

- Pump protection: Reducing strain on the pump when the system is not actively spraying.

- Safety: Prevents excessive pressure that could damage equipment or cause injury.

What are the signs that your unloader valve needs adjustment?

- Pressure fluctuations: Inconsistent spray pattern or cleaning performance

- Frequent cycling: The pump rapidly turns on and off when the trigger is not engaged

- Low pressure: Insufficient cleaning power despite proper nozzle selection

- Excessive pressure: Machine operates above its rated PSI, potentially damaging components

- Hot water bypass: In hot water pressure washers, water overheating during bypass mode

- Trigger gun leaks: Water continues to spray when the trigger is released

- Unusual noises: Chattering or hammering sounds from the pump area

- Difficulty starting: The engine or motor has difficulty starting due to pressure build-up.

Adjusting the pressure washer unloader valve: step-by-step guide

BISON has broken down the technique into four easy steps. Learn them carefully to understand the correct process so you don’t have any problem fixing. Before you start adjusting the unloader valve, please prepare the necessary tools such as wrenches, screwdrivers, and pressure gauges, and wear protective equipment such as safety glasses and work gloves.

Step 1: Turn off the pressure washer and release pressure

Shut off the engine or unplug the motor (For gasoline pressure washer, remove the spark plug wire) and squeeze the trigger gun to release any remaining pressure in the system. Allow the machine to cool completely if it has been used recently. At this point, If your pressure washer doesn’t have a built-in gauge, attach an external pressure gauge to the pump outlet or quick-connect fitting, and ensure the gauge is rated for the maximum pressure of your washer

step 2: Locate the unloader valve

Before attempting any adjustments, it is vital to find the unloader value. The easiest way to do this is to consult your pressure washer owner’s manual, if you don’t have one look for a cylindrical part with a spring or a part with pressure markings or an adjustment scale near the pump output. It usually has an adjustable knob or screw on the top.

Step 3: Adjust the unloader valve

The pressure can be increased by turning the adjuster clockwise and decreased by turning the adjuster counterclockwise. This is usually a knob, screw, or nut on top of the adjusting valve. Keep in mind that small adjustments should be made, typically no more than 1/4 turn at a time.

Keep in mind that the amount of pressure increase should be close to 10%. If you don’t make the tip exactly ten percent, you’ll need to continue turning the screw on the pressure relief valve. But still, you are not able to do this by moving the nuts to lock them, adjust the unloader valve, then the best option is to remove the washer, pressure spring, and all the screws on your pressure washer. Or loosen the nuts again.

Always pay attention to the changes in the pressure gauge when adjusting, aiming for the pressure range recommended by the manufacturer. When the pressure enters the required pressure range, continue to make smaller turns. After each adjustment, wait a few minutes for the pressure to stabilize before making further changes to avoid over-adjustment.

step 4:Test the pressure washer

Reconnect the power supply and start the pressure washer, squeeze the trigger gun to let the water flow through the system, and observe the spray pattern to check whether the pressure is stable and there is no pulsation. Then monitor the pressure gauge to ensure that the pressure remains within the required range during operation. Then verify the pressure stability of various nozzle types.

Troubleshooting common unloader valve problems

Adjusting the unloader value does not solve the problem with the BISON pressure washer, which means that there is a problem with other aspects of the pressure washer. The following are typical problems and possible solutions:

Insufficient cleaning power, weak spray, or low-pressure reading

Solution: Check and replace worn seals or valve components, check for air in the system and bleed if necessary, ensure the pump has adequate water supply

Sudden, sharp increases in pressure on the gauge or pulsating spray

Solution: Clean the unloader value thoroughly, check and replace worn O-rings or seals, or check if the nozzle or hose is clogged

Trigger gun leaks

Solution: Tighten loose fittings carefully and avoid over-tightening, replace worn O-rings or seals, inspect valve body for cracks and replace if necessary, or apply thread sealant to threaded connections

Conclusion

Adjusting the unloader valve on your pressure washer is a critical maintenance task that directly impacts both performance and safety. Users can fine-tune it to match specific cleaning tasks and prevent potential damage. BISON strongly encourages you to follow the steps outlined in this guide to achieve the best results from your pressure washer. Regular maintenance and proper adjustment will not only improve your cleaning efficiency but also extend the life of your equipment.

BISON is a well-known pressure washer manufacturer in China. We have an extensive line of pressure washers that cater to a variety of industries and applications, ensuring that dealers can find the perfect solution to meet your specific sales needs.

FAQs about pressure washer unloader valve

There are two main types of unloader valves used in pressure washers:

The advantage of the pressure regulating unloader valve is accurate pressure control and is suitable for variable flow applications. The disadvantage is that it is more complex and expensive and may require more frequent maintenance.

The advantage of the flow-driven unloader valve is that it is simpler in design, more durable, less expensive, and suitable for constant flow applications. The disadvantage is that the pressure control is less accurate and may not handle variable flow situations effectively.

This important feature prevents internal pressure from building up while the machine is running. Without it, a pressure washer can easily generate enough water pressure to damage or destroy it in a minute or less.

You might also enjoy

Questions?

Contact Us Today.

Related Products

Find more?

Related Posts

How to clean gutters with a pressure washer

In this article, we’ll guide you step-by-step on how to clean gutters with a pressure washer safely and effectively.

Why is my pressure washer leaking water?

BISON will explore the common causes of leaks in pressure washers and provide step-by-step solutions to help you restore your machine to peak condition.

Pressure washer is surging/pulsing

we’ll help you understand why your pressure washer is surging and guide you through easy steps to fix it so you can get back to

How to clean pool tiles with a pressure washer

This comprehensive guide will walk you through the steps to restore your pool tile to its original glory using a pressure washer.