A pressure washer is an incredible tool that helps us keep our homes, driveways, and vehicles spotlessly clean. These powerful machines rely on one key component – a high pressure washerr pump, which is responsible for generating a high-pressure water stream.

However, over time, the pump can become worn or damaged, affecting the performance of your pressure washer. There are a number of ways a pressure washer pump can burn out, and it’s more common than you think. Whether you let the pump run without pressure relief, crack it in storage during the off-season, or simply suffer wear and tear, pressure washer pumps can burn out and crack from time to time.

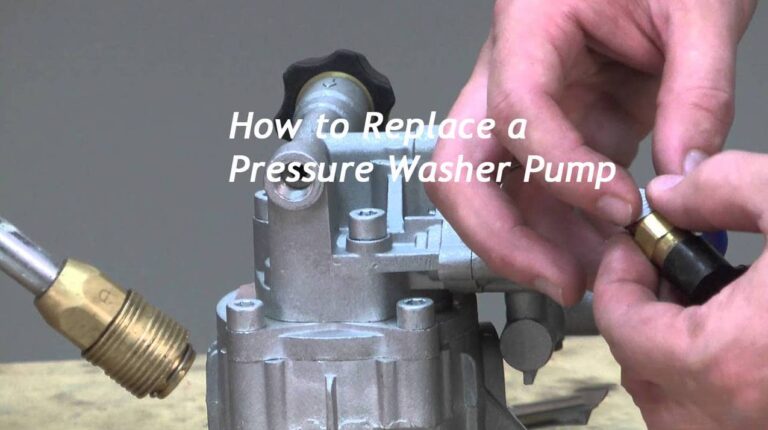

However, there is no need to throw away your pressure washer and buy a new one. Instead, simply replace the pressure washer pump. In this article, BSION– Chinese pressure washer pump manufacturer will provide you with an efficient step-by-step process about how to replace the pump on a pressure washer, while providing important safety precautions and the necessary tools and materials needed to complete the task. If you’re ready to get your hands dirty, let’s get started and restore your pressure washer to peak performance!

TIPs:Gather Necessary Tools and Parts

Equip yourself with a toolkit tailored for pump replacement. Think wrenches, pliers, and screwdrivers. Beyond tools, the right replacement pump is essential. Understand your pressure washer’s model and specifications to ensure an accurate match.

Disconnect the pressure washer and drain the water pump

First, turn off the power to the pressure washer: Find the power switch on the pressure washer and make sure it is turned off. If it is a pneumatic pressure washer, also turn off the engine. If you are using an electric pressure washer, unplug the power cord from the outlet to prevent accidental start-up.

Second, turn off the water supply: Find the water source valve or faucet connected to the pressure washer and turn it off to avoid water flowing out when the pump is removed. At the same time, release the pressure and pull the trigger on the spray gun, making sure any remaining pressure in the system is released, and hold it until the flow of water stops completely.

Finally, remove hoses and accessories: Remove any hoses or other pressure washer accessories connected to the pressure washer, including the high-pressure hose and any nozzles or wands. This will make operating the pump easier.

By following the steps above, you will ensure that the pressure washer is properly disconnected and ready to proceed with the next step of removing the pump. Safety is always a priority, so take the time to double check that all power and water supplies are turned off.

When proceeding to the second step of disassembling the pressure washer pump, be sure to drain any remaining water or liquid from the system to avoid any potential leaks or spills during disassembly. Follow these steps to drain water:

First, locate the drain plug, which is usually located on the bottom or side of the pump. Consult your pressure washer’s user manual if you need to know the exact location.

Next, place a container or bucket under the drain plug to catch the drained water.

Using an adjustable wrench or appropriate tool, loosen the drain plug counterclockwise to create an opening for water to drain out. But be careful not to pull the plug completely.

Once the drain plug is loosened, allow the water to drain completely into the container. This may take several minutes depending on the amount of water in the pump.

Finally, when the water is completely drained, use a wrench to screw the drain plug back into place to prevent leaks.

By following the above steps, you will effectively drain the water from the pump, thereby reducing the risk of a spill or leak when removing the pump from the pressure washer. Please be careful when loosening and tightening the drain plug to ensure a secure seal.

Remove the pump from the pressure washer

DIN BOLTS MOUNTING POINTS: Look for the mounting bolts that mount the pump to the pressure washer frame or engine. Typically these bolts are located on the side or bottom of the pump.

Use the appropriate tools: Depending on the type of bolt, use a wrench or socket set to loosen and remove it. Be sure to follow the bolts carefully to avoid incorrect installation.

Lift the pump safely: After removing the mounting bolts, carefully lift the pump, making sure to hold it firmly. Due to the weight of the pump, it is recommended to enlist the help of a second person to operate it together.

Review pump connections: When disassembling the pump, note any hoses, fittings, or electrical connections connected to the pump. Carefully undo these connections, making sure not to cause damage to any parts.

Set the removed pump aside: After you have completely separated the pump from the pressure washer, place it on a clean, flat surface. Doing this will allow you to carefully inspect the pump and determine if it needs repair or replacement

Installing the New Pump: Positioning is paramount. Properly place the new pump onto the pressure washer frame, ensuring a secure fit. Reattach hoses, fittings, and brackets, restoring the pump’s integrity.

Connecting the Electrical Components: Reestablish electrical connections with precision. Reconnect wires and connectors to the new pump cautiously, preventing any inadvertent damage.

Testing and Adjustment: Before powering on, ensure a final check of all connections. Now it’s time to test the new pump. Listen keenly for leaks, unfamiliar noises, and validate the pressure output. Adjustments, if necessary, ensure optimal performance.

Functional testing of high-pressure cleaners

After reinstalling the pump, the pressure washer must be functionally tested to ensure proper operation. Follow these steps to test:

1. Disconnect all connections: Carefully check all connections, including hoses, fittings, and electrical connections, to make sure they are properly closed and secured.

2. Turn on the water supply: Open the water supply valve and let the water flow into the high-pressure cleaning machine. Make sure the water supply pipes are clear and free of any leaks.

3. Start the pressure washer: Start the pressure washer’s engine or apply power according to the manufacturer’s instructions. Watch for any unusual noises or vibrations.

4. Test the nozzle: Attach the appropriate nozzle or gun to the gun and pull the trigger. Watch the water flow and pressure to make sure the spray is even and powerful.

5. Check for leaks: While the pressure washer is running, carefully check all connections, hoses, and fittings for leaks. If there is any leakage problem, solve it immediately by tightening the connections or replacing the faulty parts.

6. Check overall performance: Test your pressure washer on different surfaces to evaluate its cleaning capabilities. Check that the pressure washer is providing the required cleaning results.

7. Monitor for any issues: Keep an eye out for any unusual behavior or performance issues, such as pressure fluctuations, power outages, or unusual sounds. If any issues are found, please log them for further investigation.

By functionally testing your pressure washer, you can ensure that it is functioning properly and delivering the required level of performance. At the same time, monitoring any issues closely will help identify and resolve them before they worsen.

Conclusion: Your pressure washer’s power is reliant on a healthy pump. With safety, precision, and the knowledge shared here, you’re equipped to replace a pump with confidence. A well-maintained pump ensures your pressure washer’s longevity and unrivaled performance.

In your quest to replace a pump, remember that every step is pivotal. From safety to installation, attention to detail is your greatest ally. As you bid farewell to the old and welcome the new, keep in mind that a strong pump paves the way for cleaner, better results.