Bison Power Washer Pump

The core of any high pressure washer system is the pressure washer water pump. All BISON pressure washer pumps are manufactured on CNC machining centers with electronic control systems to ensure maximum accuracy and compliance with specifications.

BISON power provides Axial Pressure Washer Pump and Triplex Plunge High Pressure Pump. In the following, we will introduce the power washer pump matched with gasoline powered engine. Completely independent of any available power source. The power washer pump can be equipped with 5hp, 5.5hp, 6hp, 6.5hp, 7hp gasoline power.

BISON Pressure WASHER PUMPS

The Pump is the heart of your High Pressure Washer

Learn more

Find a high pressure washer pump that takes your pressure washing business to the next level.

Long-lasting quality

One of the most durable high-pressure cleaning pumps on the market, with an impressive 120-hour service life (20% higher than most pumps)

Maintenance-Free

All our pumps are pre-filled with oil and are maintenance-free. It is less hassle.

Better Than OEM

Featuring more pressure than standard original pumps. More flow rate enables you to get more cleaning done.

Chinese Pressure Washer Pump Manufacturer

Who makes the best power washer pump?

Founded in 2015, China BISON is a modern enterprise integrating design, manufacturing, wholesale, importing and exporting services. BISON is now one of the world’s fastest-growing brand manufacturers of pressure washer cleaner and high pressure washer accessories.

We specialize in the production of various pressure pump for washing machine, including vertical pressure washer pump, and horizontal pressure washer pump, etc. Because of its unparalleled reliability, it is deeply trusted by professionals and users at home and abroad.

BISON provides you with a reliable guarantee, because each part of your pressure washer replacement pumps is manufactured with the most accurate and precise machining in the world. The high quality and low maintenance cost of the power washer pump replacement will definitely increase your profits! Recognize the requirements. Grab the best ideas, provide innovative, cost-effective solutions for home, professional users, and at the job site around the real and changing needs of customers.

Whether you are an existing customer or visiting BISON CLEAN for the first time, thanks for spending time with us and look forward to doing business with you. Contact BISON immediately to send a wholesale request or ask pressure washer pump price. We will help you choose the best petrol pressure washer pump according to your needs.

In addition, we also provide pictures, PDFs, videos, etc. to help you expand your business.

How does a pressure washer pump work?

The core of a pressure washer is a high-pressure pump, and the working principle of a pressure washer pump is to convert tap water into a high-pressure, low-flow water jet driven by its own fuel or motor.

The pump has a water inlet and a high-pressure outlet, as well as a series of valves and cylinders to regulate the water flow and maintain the required pressure.

When the water pump is turned on, water enters the water inlet and flows into the pump cylinder. The piston inside the cylinder reciprocates, sucking in water and discharging it at high pressure. The resistance in the pump outlet valve creates pressure, which restricts water flow and increases pressure.

When the high-pressure water leaves the pump, it reaches the pressure washer hose. There is a high pressure washing gun at the end of the hose. When you pull the trigger, the water mixes with air and is sprayed into the pressure washer nozzle. However, the diameter of a pressure washer nozzle orifice is much smaller than the diameter of the pressure washers hose, so converting high-pressure, low-flow water to low-pressure, high-flow water requires accelerating the water through the nozzle. there is. water. flows. The nozzle design regulates water flow and pressure to produce precise water flow that can be used to clean a variety of surfaces.

Among the common high-pressure water pumps on the market, plunger pumps are the most common due to their high efficiency and long life. These are typically made of hard, wear-resistant ceramic and can be described as plungers that move back and forth against a fixed seal or packing. By comparison, piston pumps have better starting characteristics, but cannot operate at the same high pressures and have a shorter service life.

How a plunger pump works: Water is drawn into the pump cylinder cavity through an inlet check valve, the inlet valve closes as the plunger moves forward, and the water is forced through a series of outlet valves to the pump discharge port. Masu. This process is similar to how an internal combustion engine works, with the intake valve pumping gas into the engine on the downstroke, the intake valve closing on the upstroke, and the exhaust valve opening. Most plunger pumps are double or triple cylinders, but triple cylinders are most commonly used in pressure washers as they allow for a smoother flow of water. Newer, faster pumps reduce pressure fluctuations and require less starting torque, but can wear faster, reduce suction lift capacity, and produce noise.

The volume of a plunger/piston pump depends on the speed of the pump. That is, the liquid coming in must come out at the same speed. Therefore, it is important to install safety devices such as unload valves and safety relief valves in the system to prevent hazards due to blockages.

Generally, the high pressure washer pump is an important element that converts tap water into a high-pressure, low-flow water jet, and its working principle relies on a power source to drive the pump piston to produce a high water flow. Masu. pressure water jet. A pressure washer’s pump plays a key role in producing the high-pressure water flow needed to effectively clean and remove dirt, grime, and other debris from surfaces.

What Is The Difference Between Axial And Triplex Pump?

The main difference between axial and triplex pumps is the number of pistons they have. Axial pumps have one piston, while triplex pumps have three. This difference in design affects the performance and lifespan of the pumps.

Axial pumps are smaller and lighter than triplex pumps, making them more portable. They are also less expensive. However, they have a shorter lifespan and cannot produce as much pressure as triplex pumps.

Triplex pumps are larger and heavier than axial pumps, making them less portable. They are also more expensive. However, they have a longer lifespan and can produce more pressure than axial pumps.

Here is a table that summarizes the key differences between axial and triplex pumps:

| Feature | Axial Pump | Triplex Pump |

|---|---|---|

| Number of pistons | 1 | 3 |

| Size | Smaller | Larger |

| Weight | Lighter | Heavier |

| Price | Less expensive | More expensive |

| Lifespan | Shorter | Longer |

| Pressure | Lower | Higher |

Ultimately, the best way to choose the right pump for you is to consult with a pressure washer expert. They can help you assess your needs and recommend the best pump for your specific application.

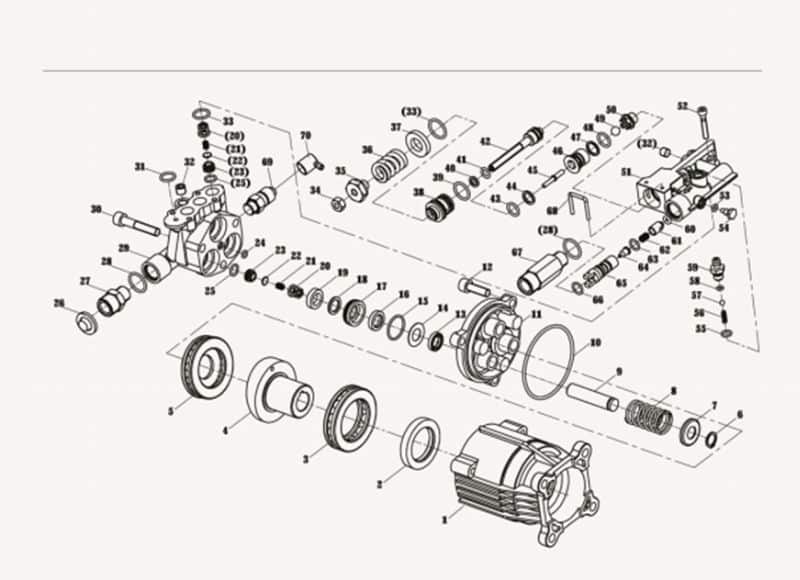

What’s a real pressure washer pump like inside?

~Pump Chamber(1): This is the chamber where water is pumped to high pressure.

~Pump Piston(11): They move back and forth (reciprocates) to convert the water to a high-pressure jet.

~Pump Valves(29): Control the direction of the water to make the water move in one direction. There are 6 valves in each pump.

Power Washer Pump Application

- Wash bicycles, motorcycles, cars, trucks, trailers, tractors, boats, etc.

- Clean driveways, garage floors, sheds, fences, fences, etc.

- Clean outdoor play equipment, such as slides and swings

- Clean outdoor furniture, garden furniture

- Clean smelly wheeled trash cans

- Clean kennels/kennels, chicken houses, etc.

- Clean various equipment, such as lawn mowers, mountain bikes, trailers, grills, go-karts, etc.

- Clean concrete or tiled terraces

- Clean up the sewer

- Clean the main entrance stairs, walkways, wooden decks, house siding and brick houses

Advantages And Features of Power Washer Pump

【Extended Durability】

High-performance double seal system prevents leakage, upgraded technical surfacing piston and bearing, get 120 hrs running time, longer than OEM petrol power washer pump.

【Thermal Relief Valve Protected】

And the thermal relief valve (TRV) protects the high pressure washer water pump from overheating while in bypass mode.

【Maintenance-Free】

This high pressure cleaner pump features a maintenance-free crankcase so you never have to change the machine oil.

【Easy Start】

The built-in simple and quick cold start makes it easy to start without releasing the pressure before starting the engine. Bison gas pressure washer pump can make your machine run as quickly as possible and complete the setup in 5-10 minutes!

【Better Performance】

The BISON high pressure washer pump comes standard with a larger 2.5 GPM flow rate, allowing you to complete more cleaning tasks faster. It has a higher pressure than the standard original pump. The pump is rated at 2800-3000 PSI and 2.5 GPM, which is very suitable for any and all small house cleaning projects.

Bison Pressure Washers Features

- Save money by replacing the pump instead of purchasing a new pressure washer. Top preformance from 2800-3000 PSI and replaces most rear export 180-196cc, 6.5-7 hp engines.

- High-performance, double seal system, prevents leakage, upgraded longer than the original power washer pump. A thermal relief valve (TRV) prevents the pump from overheating in bypass mode. With an adjustable unloader, you can increase or decrease pressure to better match your engine’s demands.

- Bison pressure washer pumps adopt a maintenance-free crankcase, so you don’t need to change gasoline. This easy-to-install kit is perfect for power washers, which can support 3000 PSI at 2.5 GPM to wash walls, fences, sidewalks, vehicles and more.

- Bison pressure washer pumps are also suitable for front intake/ exhaust engines, but you need to rotate the pump 180 degrees and drill holes in the frame to install the pump. If this is difficult, go straight to the forward/ outlet pump.

- Built-in simple and fast cold start function, making starting a breeze; no need to release the pressure before starting the engine. Each kit includes a siphon with filter, mounting bolts, shaft key, and instructions to get your machine back up and runing in 5-10 minutes to set up!

- Better wear and friction resistance extends seal life

- Rugged, corrosion resistant

- Fully anodized die- cast aluminum for corrosion protection

- Releases a small amount of hot water and draws in cooler water to extend pump life

How to Install and Use Bison Horizontal/Vertical Pressure Washer Pump

1. Using the Allen wrench, loosen the bolts on the top of the pump.

2. Lightly rock the head back the forth to pull the pump of the engine shaft.

It maybe seized to the shaft, so if it is try some penetrating oil. After allowing the penetrating oil to do its job gently pry the pump loose or use a bearing puller to pull it off.

3. Watch for the key falling out sine you will need it to install the new pump.

4. Clean the shaft with emery clot then apply a light coating of anti-seize or oil on it.

5. Using a bit of grease, “glue” the key in the engine shaft keyway to help keep it in place.

6. Slide the new pump on the shaft ensuring the key stays in place

7. Turn the pump to match the pump bolt holes to the engine bolt holes. Install and tighten the bolts to secure the pump to the engine.

8. Connect your hose and as usual have a try.

Power Washer Pump Maintenance

What Cause Power Washer Pump Failure? And How to repair a petrol washer?

Power washer pump failures can be caused by a number of factors, including

1. Overuse or improper use can cause the pump to overheat and fail.

2. Improper maintenance such as neglecting to change the oil and low oil levels

3. Dirty water can also damage the pump.

4. Improper storage and extreme weather can also lead to pump g failure Follow

Besides, several indicators will show a faulty cleaning pressure washer pump. The most common are leakage, pulsating output pressure and low output pressure. Leaks are usually caused by worn or damaged pump seals. The pulsating pressure indicates that there is not enough water in the pump. Low pressure is usually caused by worn O-rings or a clogging of dirt at the pump inlet.

How Long Does A Pressure Washer Pump Last?

The life expectancy, of those pumps is around 100 to 120 hours of continuously use.

Does Pressure Washer Pump Need Oil?

This pump features a maintenance-free crankcase so you never have to change the machine oil.

Pressure Washer Pump Troubleshoot

| TROUBLE | PROBABLE CAUSE | REMEDY |

|---|---|---|

| Fluctuating pressure | Pump sucking in air | Check connection are tight |

| Valves dirty, worn out or seized | Contact customer helpline | |

| Blocked jet | Remove blockage using jet cleaning tool | |

| Water leakage from pump | Seals worn out | Contact customer helpline |

| The pump does not reach the required pressure | Pump sucking in air from connections or hose | Check tightness of all connections |

| Suction/delivery valves are clogged | Clear or replace valves. Have machine checked by Service Centre | |

| Unload valves are stuck | Loosen and re-tighten regulating screw | |

| Lance or nozzle worn out | Check and/or replace | |

| Pump is running but no water delivery | Kinked inlet and or pressure hose | Check, straighten and replace if required |

| Blocked inlet filter | Remove and clean filter | |

| Blocked jet | Remove blockage using the jet cleaning tool |

CONTACT US TO KNOW MORE BISON PRESSURE WASHER